Applying images to various surfaces

We use different types of printing in

For very large print runs with low requirements for mechanical stability of the image, offset printing is usually used.

If you need to apply an image to one or more units, and the shape of the product or material allows it, it is rational to use digital printing.

For curved surfaces in medium and large runs, pad printing is best.

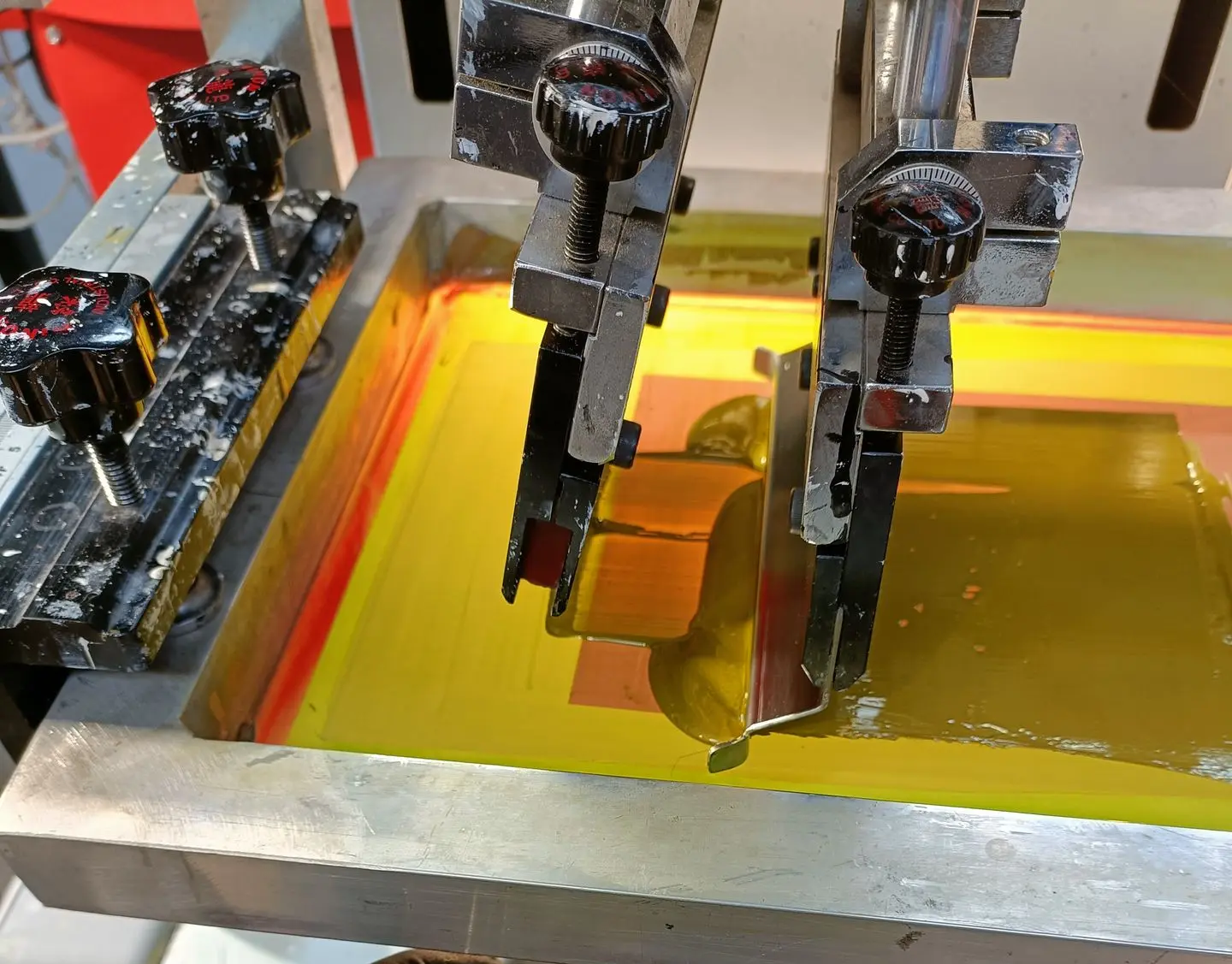

For sheet materials, as well as products with a flat or cylindrical surface, we use screen printing.

Advantages of screen printing

Strength

For each material, we use a specially selected ink for the best adhesion to the printed material, as well as mechanical and/or chemical resistance.

Versatility

Screen printing is one of the most effective methods of applying images to surfaces used in vacuum forming, which in turn allows you to adapt the production process to your own needs.

Brightness

The paint is applied through a special polyester or metal mesh onto the surface of the material, resulting in a high layer of paint with extremely saturated colors that do not lose their intensity over time.

Profitability

Screen printing is cost-effective for large production runs. The cost per unit decreases as the print run increases.

Branding examples

What do we offer?

We offer professional screen printing services, guaranteeing high quality, speed of execution and an individual approach to each client. Our team has extensive experience in this field and uses modern equipment, which allows us to achieve the best results.

How to place an order?

Contact us today to discuss your order and receive a consultation.

We are ready to help you realize your ideas and create unique products,

that will attract the attention of your customers.